Waiouru Wastewater Scheme

The NZ Army owns and operates the Wastewater Treatment Plant in Waiouru. Council owns and maintains pipelines from the civilian properties and the Waiouru Army Museum to the Wastewater Treatment Plant.

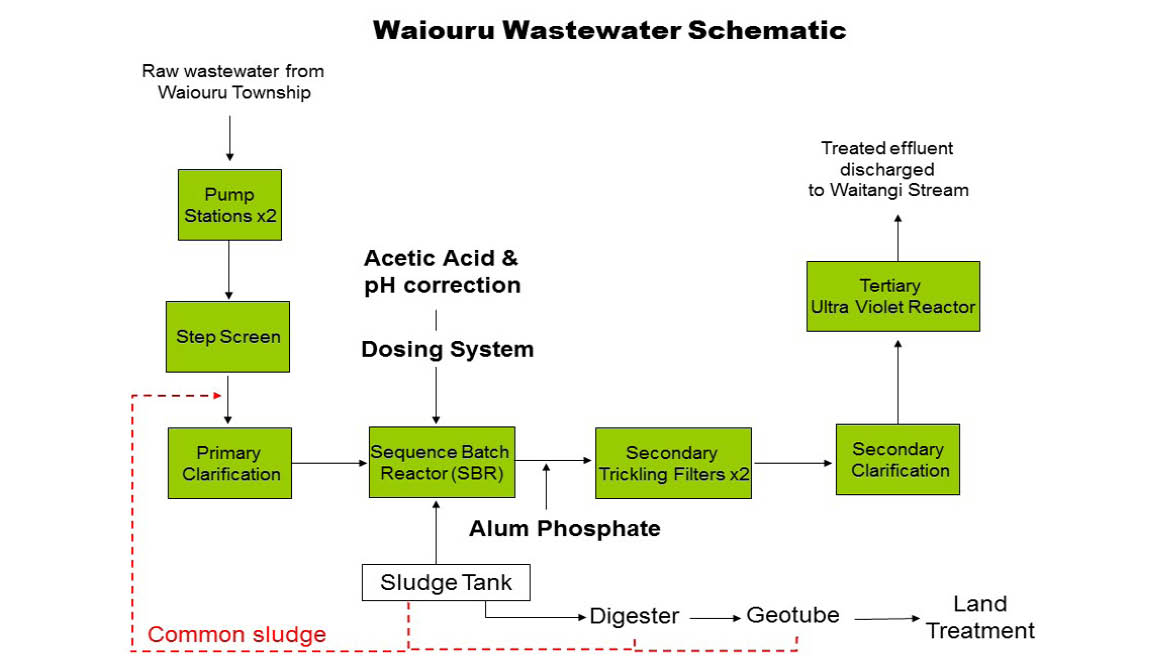

The below schematic shows flow through the network:

The pipelines

Wastewater is transported through 2.4km of Council owned pipelines to the NZ Army Wastewater Network. A map of the Council owned collection network is provided in the link at the bottom of this page.

Wastewater Treatment Plant

Wastewater is transported to the Waiouru Wastewater Treatment Plant (pictured below), where it is treated prior to discharge.

The Waiouru Wastewater Treatment Plant provides treatment of wastewater through the following steps:

1. Primary Treatment

1.1Step Screen: Raw wastewater arriving at the Wastewater Treatment Plant is passed through a screen with holes in it. Fluid wastewater and smaller solids pass through the holes and on to the next step in the treatment process. Larger solids, including wetwipes, rags, and other rubbish items that end up in our wastewater system, are retained by the screen as they are too big too fit through the holes (a bit like a large scale sieve).These items must be disposed of to landfill.

1.2Clarification: Screened wastewater is piped into a primary settling tank (clarifier) where larger solids (small enough to pass through the screen) settle to the bottom. Solids which settle to the bottom in this process are passed to a sludge tank, the contents of which are recycled to the head of the treatment process and mixed with incoming wastewater to go through the process again.

2. Secondary Treatment

2.1 Sequence Batch Reactor (SBR): Wastewater from the settling tank is piped to a SBR (shown below) where bugs are used to aid nitrogen removal. Too much nitrogen in wastewater can cause problems as when it is discharged to a waterway it can cause algal bloom which depletes oxygen levels in the water and may cause death to aquatic animals.

Acetic Acid is added to the SBR to provide carbon which is required in the biological reactions which take place in the nitrogen removal process.

2.2 Phosphorus removal: Treated effluent is dosed with alum phosphate to remove phosphorus. Phosphorus is similar to nitrogen in that, when levels are high, it can cause algal bloom and deplete oxygen in waterways, harming aquatic animals. Large mats of algae can also smother insect homes, which means less food for other aquatic insects.

2.3 Trickling Filter: Wastewater is applied evenly over a bed of stones (called media). Bugs and algae grow on the media, creating a film of slime. As the slime layer grows and gets thicker the bugs where the media touch each other have difficulty getting enough oxygen and food to survive and so begin to get it by breaking down remaining suspended solids (small solid particles held in suspension in water) in the wastewater. The slime gets so thick that it cannot hold onto the rock any longer and falls off and is replaced with new growth.

The figure below shows the two Trickling Filters at the Waiouru Wastewater Treatment Plant sitting behind the Primary Clarifier.

2.4 Clarifier: Wastewater is piped from the trickling filters into a secondary settling tank (clarifier) where remaining solids settle to the bottom. This is a process similar to that which took place in the Primary Clarifier. Below is a figure of the Secondary Clarifier at the Waiouru Wastewater Treatment Plant.

3.Tertiary Treatment

3.1 Ultra Violet (UV) irradiation: Wastewater is further treated by exposure to Ultra Violet light. This kills any bacteria and viruses remaining in the wastewater by destroying their genetic core (DNA). It is also effective against many protozoa.

The treated wastewater from the Wastewater Treatment Plant is discharged into the Waitangi Stream.

4. Sludge Treatment

Heavy solids or muck removed from the wastewater and remaining at the end of the process is known as sludge'. Sludge treatment is focused on reducing the amount of water in the sludge to reduce weight and volume, which reduces transport and disposal costs, and also on reducing potential health risks of the remaining matter.

4.1 Sludge Tank: The sludge tank collects all the sludge which has resulted from the stages of treatment of the wastewater. This includes sludge from the Clarifier, the SBR and the Trickling Filter. As sludge settles in the sludge tank, the heavier solids sink to the bottom leaving the water floating on top. The water is taken from the top and returned to the head of the treatment plant to go through the process once again.

4.2 Digester: Thicker (soup like) sludge is pumped from the sludge tank into a sealed container called a digester where it is stirred continuously, ensuring that oxygen is mixed in well with the sludge. There is still lots of food in this solid waste and bugs use this to make more bugs, until eventually there is no food left and they die. This process helps to reduce the volume and weight of the sludge by making it go from a liquid, soup like, consistency down to a more solid cake like mix. Any remaining water in the sludge floats to the top and is taken off and returned to the head of the treatment plant to go through the process once again.

4.3 Geotubes: Digested sludge is pumped to Geotube membranes (pictured below). These are bags which allow water to drain through the membrane thus helping to dry out the sludge which reduces the weight and volume left to be disposed of. Water which is drained off is returned to the head of the treatment plant to go through the process once again. When these bags are full the contents are discharged to land which has been set aside for this purpose.

Waiouru Wastewater Collection Network Map

- Waiouru Wastewater Collection Network (PDF, 167.7KB)